Our Quality Initiatives

Quality Control Process

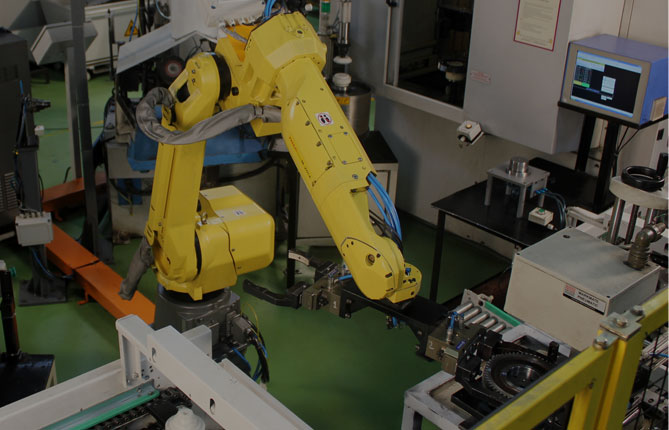

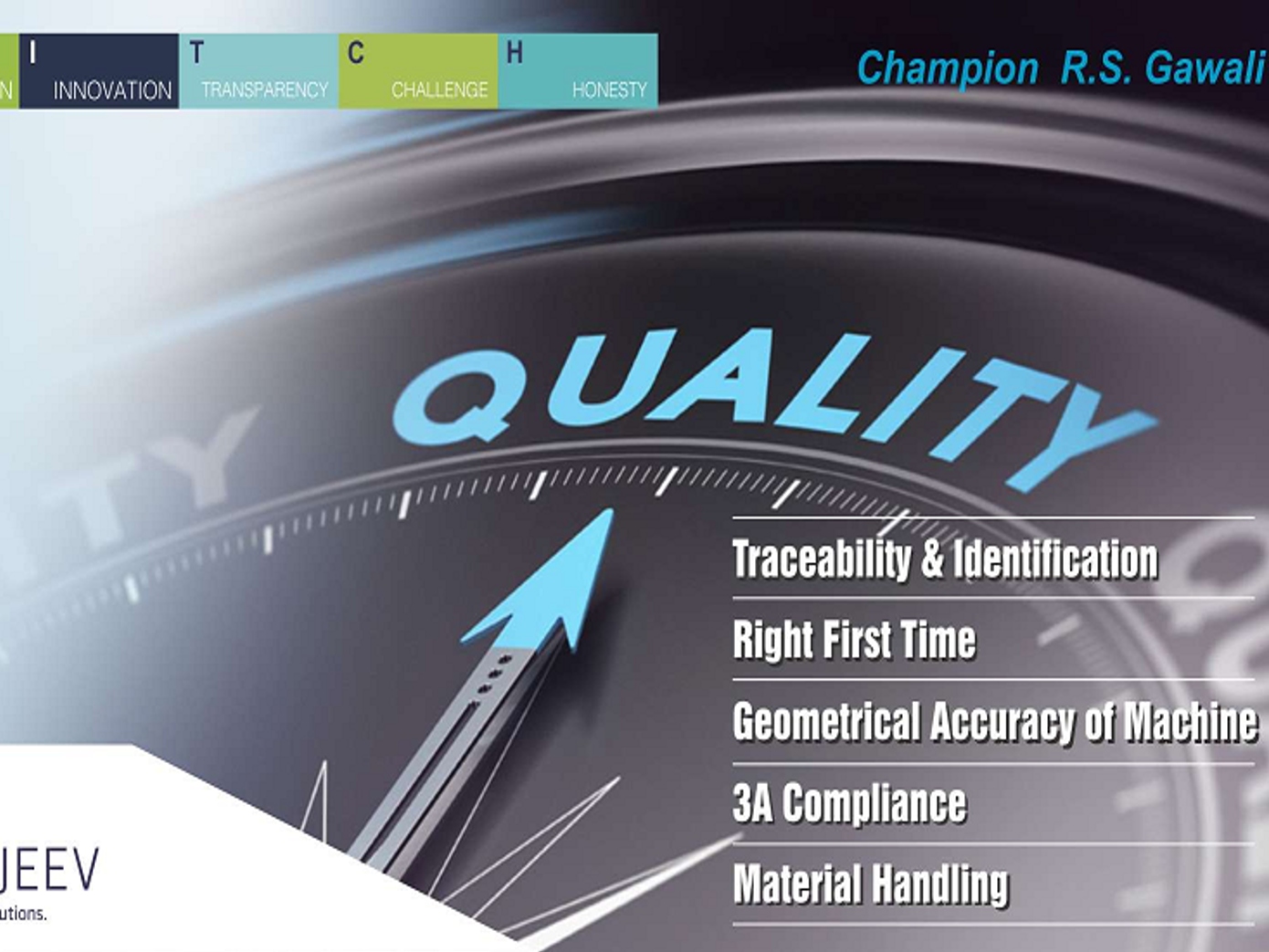

We take pride in adopting the latest technologies and equipment to achieve near Zero Defect production processes, helping us meet the highest standards and expectations from our global OEM clients.

INPUT-PROCESS – OUTPUT quality integrated with robotic auto-inspection and error proofing and detection

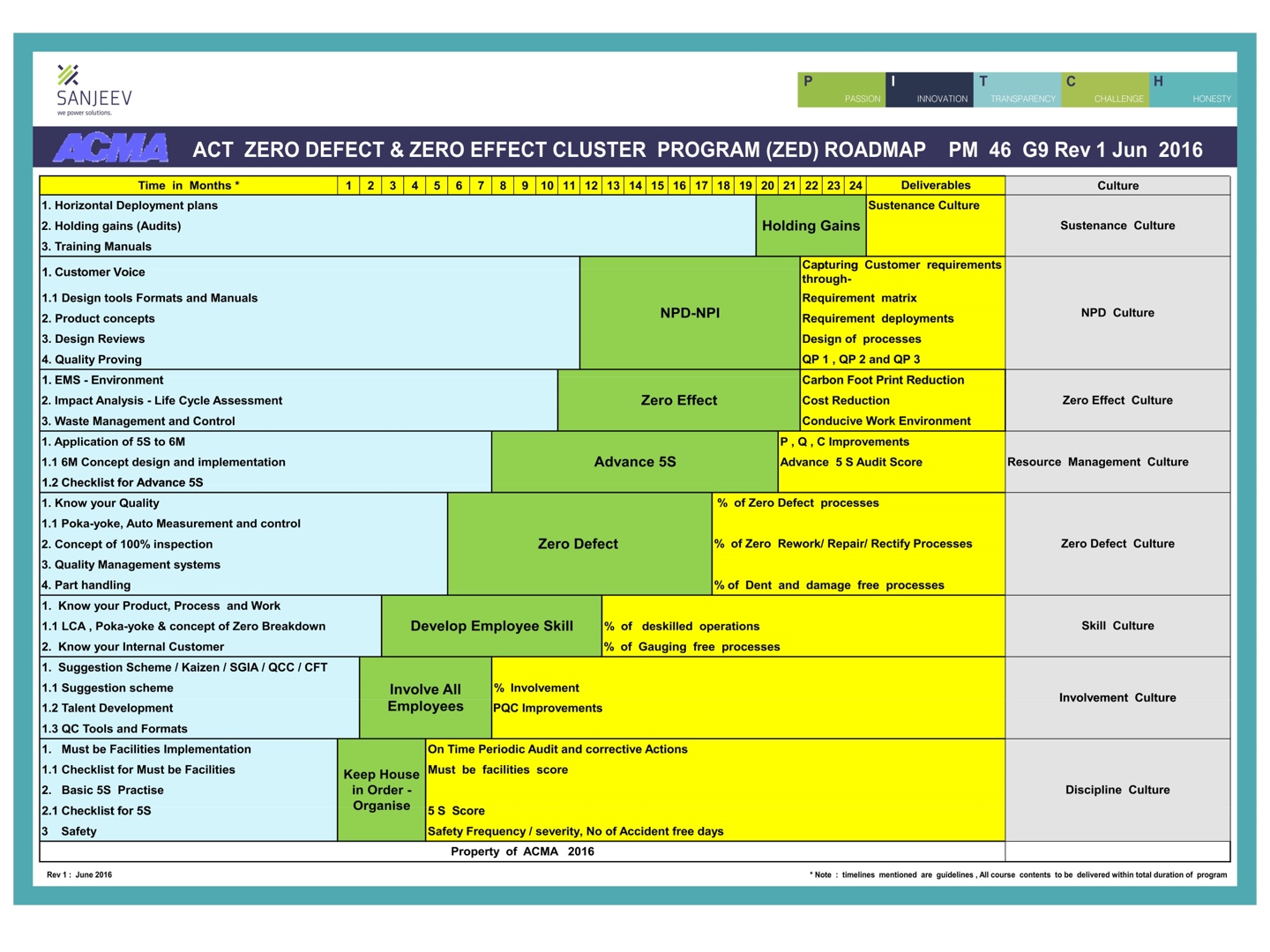

Monthly reviews towards ZERO Defect, ZERO Effect outcomes

Quality Circle/SGA to address customer complaints, in-house rejection, VA/VE and water and energy conservation

Theme-based P.I.T.C.H. monitoring to ensure holistic quality improvement and performance sustainability

Annual Six Sigma Day celebration including project assessment and customer evaluations

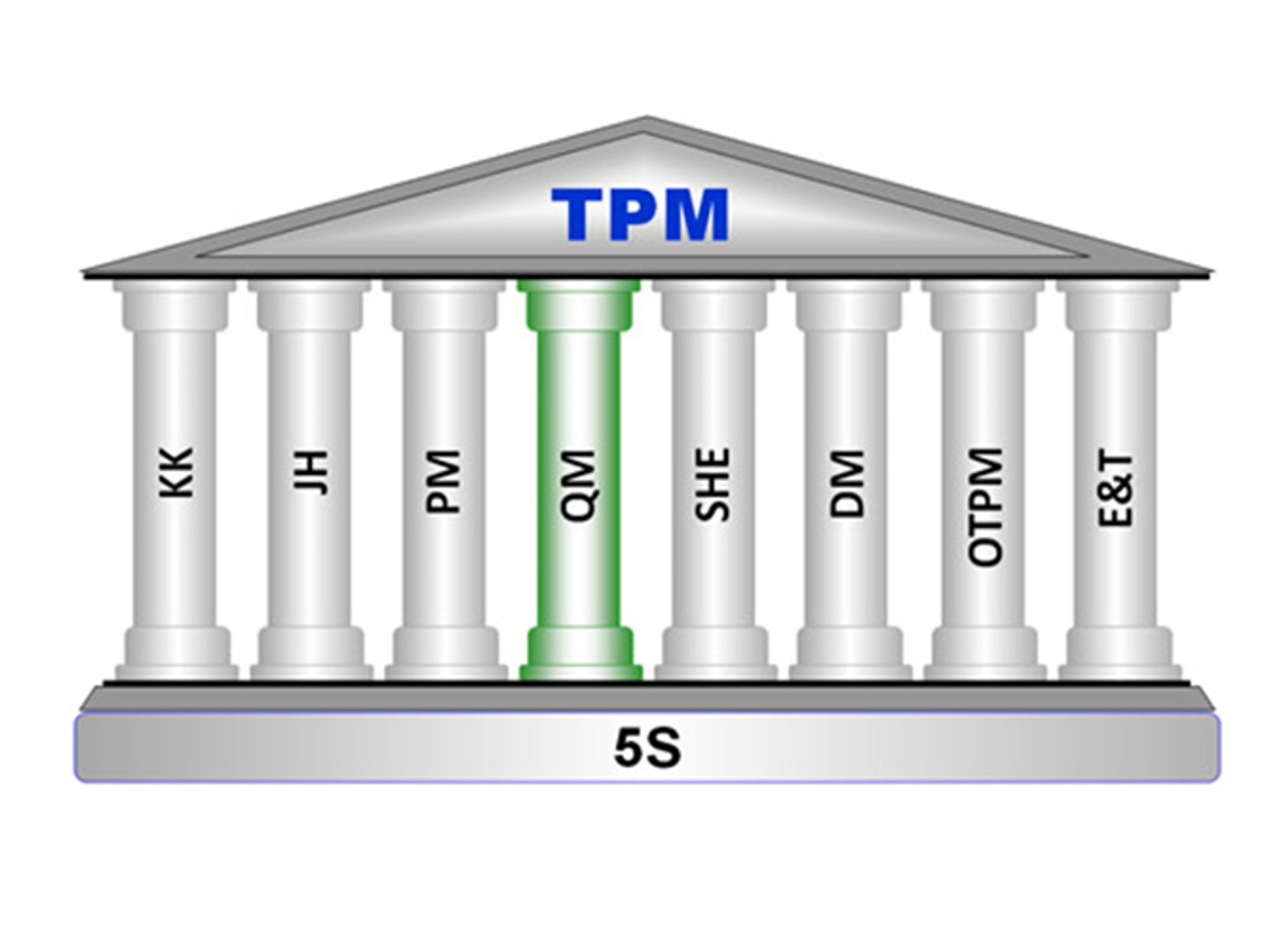

Quality modules based on application of TPM culture and processes

More about Our Plants & Facilities

Metrology & Metallurgy Equipment

At Sanjeev we believe that achieving sustainable quality requires more than the latest technology, which is why we supplement it with a strong focus on quality control and process management.

Klingenberg – Gear Analyser

TTI-Gear Tester

Auto DFCE Inspection

CMM

Millipore Testing Equipments

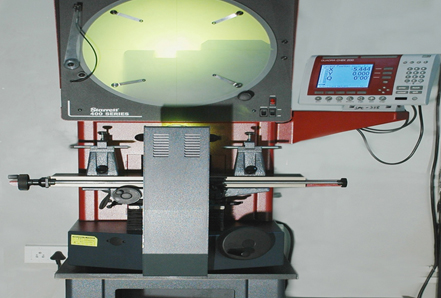

Profile projector

Trimos – 2D Inspection

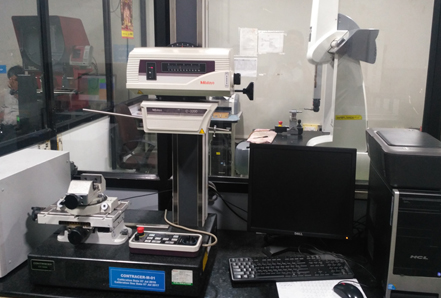

Contressor – Conture Measurements

Spectro Machine

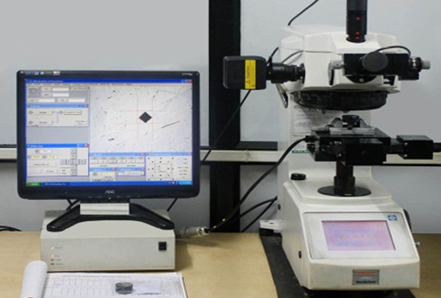

Micro hardness tester

Microscope