7 State-of-the-Art production facilities

plants and facilities

Overview

We believe that manufacturing quality is almost inevitably an outcome of process, design and technology. These are the principles around which our production facilities across the globe are designed – by adopting the best processes, focusing on good design and investing in the best technologies.

Each Sanjeev facility, from the first established in 1978 to the latest which opened in 2011, has been established with these principles and undergoes frequent upgrades to remain state-of-the-art. The most critical ingredient however, are the skills, experience and commitment of our team of manufacturing specialists who have over four decades of experience meeting the expectations and needs of the leading automative brands in India and across the globe

Gear and Excellence Division K96- Aurangabad, India

Key Features & Capabilities

• Hobbing with orientation, Multi hobbing, Soft Hard Skiving

• Generation Grinding with corrundum, Profile Grinding with corrundum

• Profile Grinding with CBN, Burn Free Gear Grinding

• Through feed & plunge serration rolling 25T

Key equipment

Liebherr Hobbing with Ring Loader & KSR, Gleason Vertical hobbing 130H, Liebherr Gear Grinding LCS380, Profiroll Spline Rolling Machine, Vibro finishing, Traceability Laser marking

Profile Grinding

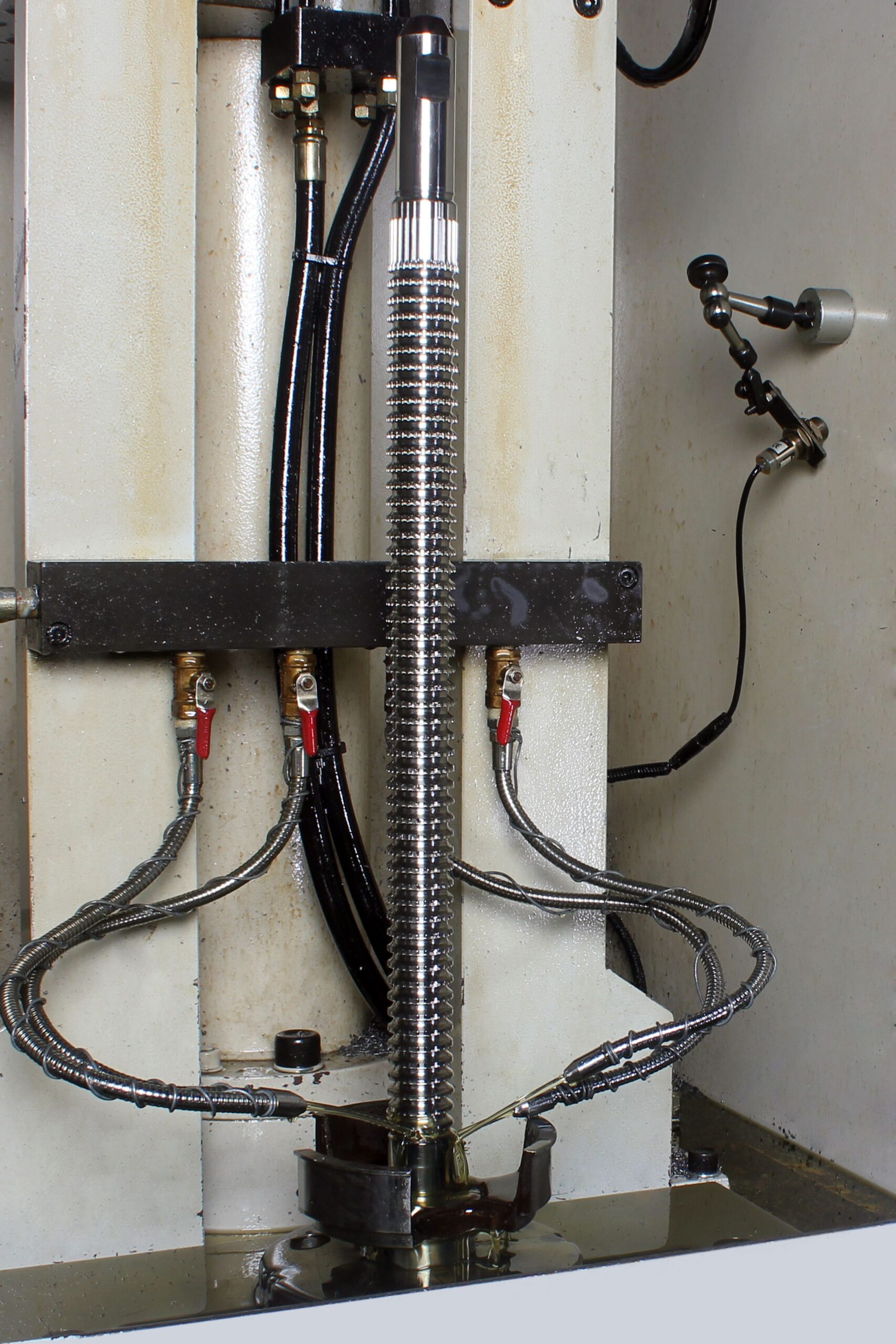

Spline Rolling

Grinding Machine

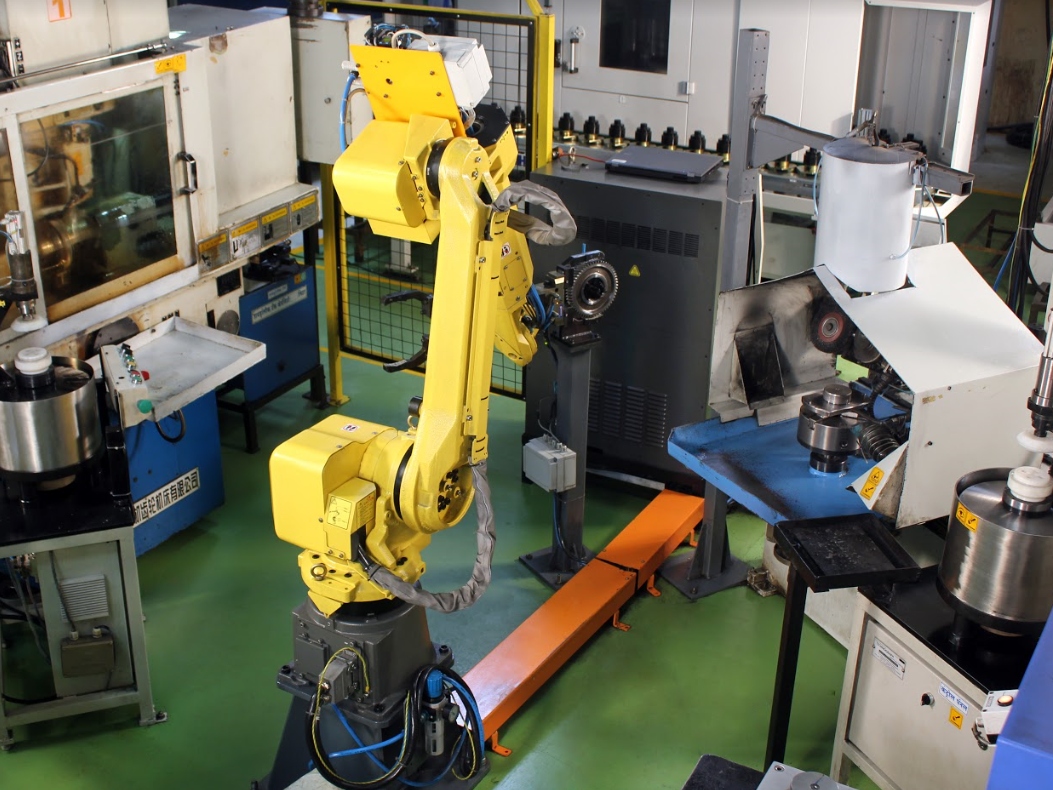

Soft Cell

Assembly Division C7 – Aurangabad, India

Key Features & Capabilities

• Hobbing with orientation, Multi hobbing, Hard Skiving

• Tooth rounding, High speed Hobbing

• Through feed & Plunge Serration rolling 10T

• Broaching 5T, Ratchet Milling• Automated gear inspection with assembly

• Single pass diamond bore finishing (Honing)

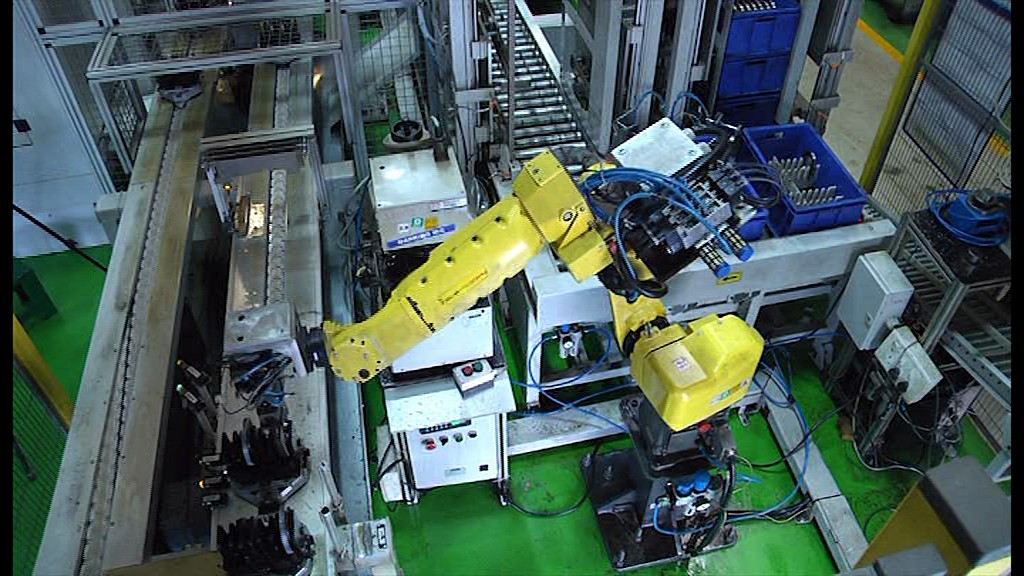

LC180 Hobbing

Gleason P-90 Gear Cutting

CNC cylindrical grinding

Honing machine

Metal Forming Division M115 – Aurangabad, India

Key Features & Capabilities

• Die machining with simulation

• Precision Components machining with 4th and 5th axis facility

• High speed bar cutting

• CO2 welding and Induction hardening

• Vertical broaching 10 Ton up to Length 1500mm

Key equipment

Hot Forging press 1000 Ton with QCD. Hot Forging press 1600 Ton with QCD, Induction Billet heater with Temperature, Pokauoke. Pallet Changer VMC. CNC

CNC Machining

VMC Broaching

Broaching

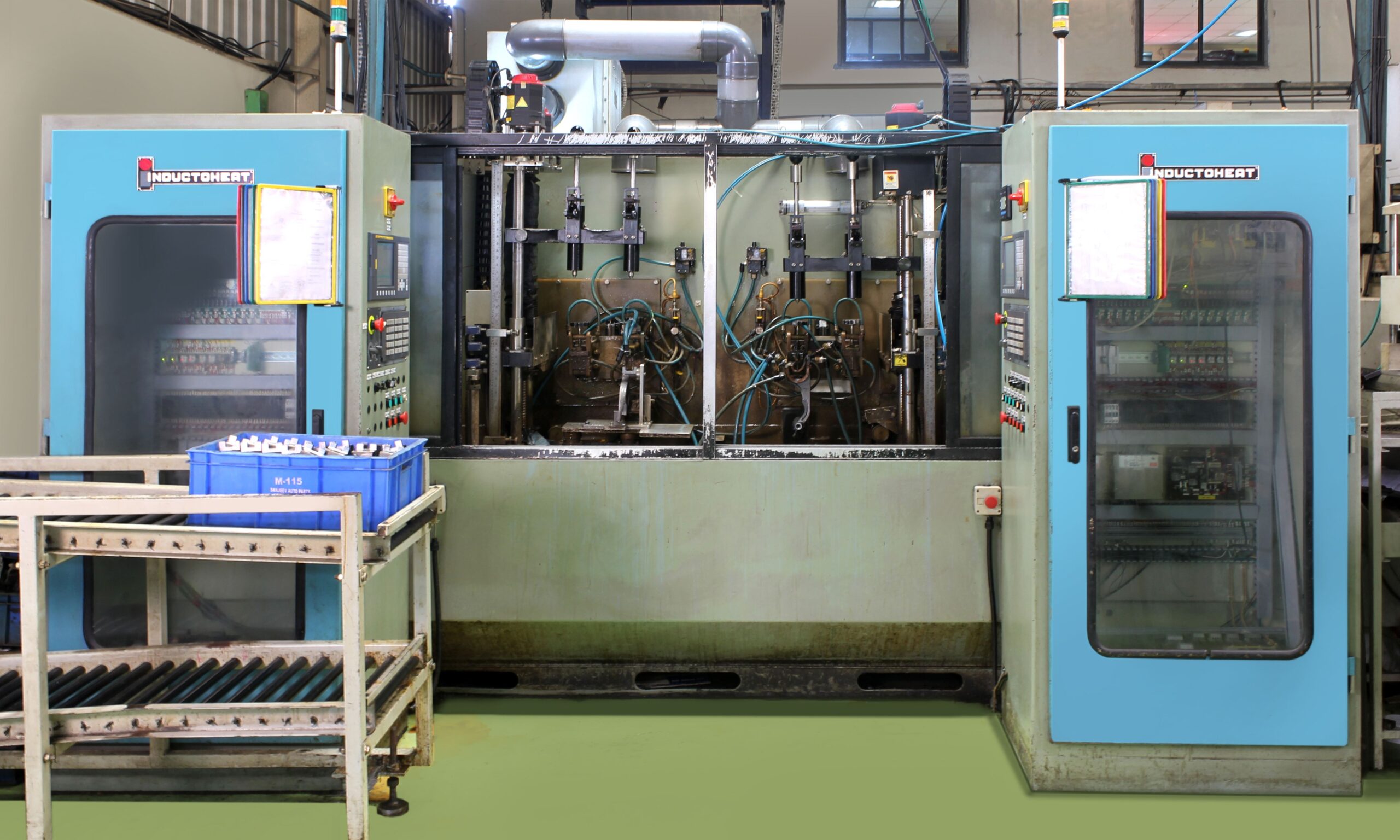

Induction Hardening